Ball valves are one of the best and most widely used options for controlling gas and liquid flow in a variety of systems including food production plants, water management systems, as well as residential beer brewing, winemaking plumbing and more. With minimal rotating through your lap seal, their design-ball on a spherical body with a bore allows pressure tight shutoff when closed and very low flow resistance when open. Understanding when and why to use Valve manufacturer India is essential for efficient plant operation, enabling engineers and maintenance teams to optimize system performance while minimizing operational costs and unplanned downtime.

Core Advantages of Ball Valves

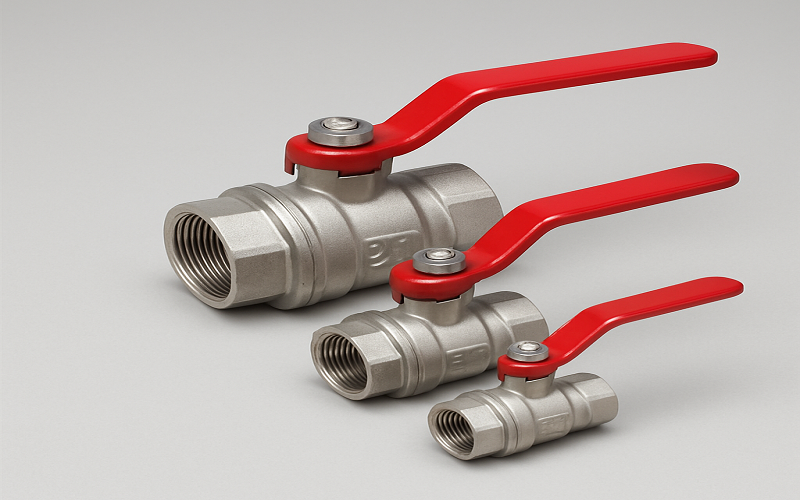

Ball valves are best for situations where on/off control is required as opposed to when throttling is needed. The full bore design enables free flow that is equal to the size of the pipe, which minimizes pressure loss in globe or gate valves. Weather-resistant, heavy-duty materials such as stainless steel, brass, and PVC make these pumps ideal for water and a variety of other liquids from corrosive fluids to non-abrasive vinegars. Multi-Way versions (2-way, 3-way, 4-way) allow for intricate flow angle reversals in a single block. Their reduced maintenance requirements and long life also make them economical for high cycle applications.

Full Port vs. Reduced Port Option

Full port ball valves preserve pipe ID through the bore acting as a clean pigging in various pipeline or flow sensitive applications. They are more expensive, but provide the highest Cv values. Reduced port valves have smaller bores than pipe ID resulting in some constraint but with reduced cost and weight. Full port design is available for oil/gas transmission which the flow resistance should be as less as possible; Use reduced port when cheaper and in time signal is your preference in instrumentation or low-flow HVAC systems. Reputed valve manufacturers India offer a wide range of both full port and reduced port valves for domestic and international industries.

Material Choices for Specific Environments

Corrosive, high-temperature and hygienic applications such as food processing and pharmaceutical rely heavily on stainless steel ball valves. Brass is suitable for use in water, oil, and gas applications. Steel, carbon it is suitable for high-pressure hydrocarbons but needs coatings to handle exposure to water. PVC and CPVC are used for low pressure chemical lines at economical costs. And the most otherworldly alloys, like Hastelloy or Monel, take on powerful acids or seawater. Match wetted parts to media pH, temperature, and pressure per application requirements at all times.

Pressure and Temperature Applications

Normal ball valves are suitable for pressures up to 1000 psi in ambient temperature, whereas high-pressure (trunnion-mounted) designs reach more than 5000 psi for use on offshore pipelines. Cryogenic service extensions keep stems free from freeze-up in LNG service to -320°F and fire-safe API 607 valves retain integrity under metal-seated fire at 2000°F. A more common use in industry is to the control intricate switching say in HVAC zoning or mixing for chemical dosing. Choose ratings higher than maximum system pressures with margins of safety

Actuation Options for Automation

Manual levers are available in sizes up to 6 inches for infrequent on/off service. Larger size valves are equipped with gear operators to multiply required torque. Electric actuators can be connected with PLC for accurate positioning and remote monitoring. Hydraulic versions to function by quarter turn are available for subsea or heavy duty applications. Motorized ball valves save on labour and provide SCADA connectivity between sites.

Use enhanced ball valves for clean service with tight shut-off and low pressure drop. Vibration Damage Avoidance they perform better at partial open positions than those of gate valves. Globe valves throttle better, but are too drippy. Butterfly valves help you save space, but tend to leak a bit more under pressure. Features Standard and full port sizes Bi-directional, bubble tight shut off in.5s Flow through design ideal for viscous and sticky liquids Applications Use ball valves for oil/gas isolation, water shut-off, steam service or on slurry lines where fast emergency shut off is critical. Ball Sticking or Precise Throttling Avoid sticky slurries susceptible to ball sticking or fine regulating that requires a linear response.

Maintenance and Longevity Factors

Planned packing modifications guarantee leak free performance and reduce fugitive emissions. Proper seat cleaning prevents sticking caused by debris or waste build-up. Regular lubrication significantly extends actuator life, especially in dirty operating environments. Ultrasonic thickness testing enables early detection of corrosion in aggressive media. Replaceable trim components help extend service intervals and reduce downtime. Applying correct torque values during assembly prevents seat damage caused by over-stressing. Ball valves normally have a service life of ten to twenty years with little maintenance when properly matched to service circumstances.

Ball valves are widely used for isolation across many industries because they work reliably under different pressures, temperatures, and media conditions. Choosing the right port type, material, actuator, and pressure rating is essential for safe and efficient performance. Referring to manufacturer flow charts and pressure temperature ratings during selection can help avoid expensive mistakes. Whether in water supply systems or petrochemical plants, ball valves continue to be a dependable industrial standard.