The most effective method to DISSIPATE HEAT

What are Heat Sinks Used For?

Hotness sinks are utilized in electronic gadgets and gatherings to give supplemental cooling that is needed to forestall overheating of parts. These components are planned and improved to guarantee that electronic gadgets work inside the temperature ranges given by makers.

Regardless of the huge assembly cost decrease of electronic loads and nooks for gadgets, it is as yet an overwhelming and tedious undertaking to break down the warm exhibition of another plan. Download this contextual analysis to figure out how to disperse heat, and the warm presentation of a printed circuit board was examined utilizing warm examination in an internet browser.

Hotness sinks are planned utilizing warm conductive materials—like copper and aluminum—and they work by dispersing heat through fluid cooling, normal convection, constrained convection, or radiation. Warm administration needs change starting with one application then onto the next. Subsequently, it is vital to look past the heatsink when planning a warm answer for a specific application. Some of the key factors to consider include heatsink-level requirements, component-level requirements, system-level requirements, and chassis-level requirements.

- Hotness SINK DESIGN

- Key Considerations in Heat Sink Design

- the most effective method to disseminate heat sink plan CAD model

- Computer aided design model of a hotness sink

A heat sink moves the heat generated by an electronic assembly or component into a cooling medium. Specifically, heat moves from a higher temperature region (the electronic component) to a lower temperature area (the liquid medium) through conduction, convection, radiation, or a combination of these heat transfer methods.

Heat sink plan warm examination how to scatter heat

Form heat move investigation of a hotness sink ran in an internet browser with SimScale

In this project, the heat flow in a heat sink design was simulated. To utilize it as a format, simply make a free Community account here and afterward duplicate the undertaking.

1. Warm Resistance

Thermal resistance refers to the amount of resistance to heat flow between the transistor and the coolant fluid. Specifically, these heat flow resistances include the resistance between the transistor and the device casing, the resistance between the casing and the heat sink (thermal interface resistance), and the resistance between the heat sink and the flowing fluid. However, thermal resistance does not account for non-uniform heat distribution, and therefore, it is not suitable for modeling systems that are not in thermal equilibrium.

- heat sink configuration lattice of a gadgets fenced in area made with SimScale

- Cross section of a hardware fenced in area made with SimScale

2. Material

Designers plan heat sinks using materials with high thermal conductivity, such as aluminum alloys and copper. Copper offers magnificent warm conductivity, antimicrobial opposition, biofouling obstruction, consumption opposition, and hotness retention. Its properties make it a magnificent material for Lenovo ThinkPad Fan however it is more costly and denser than aluminum.

3. Course of action, Shape, Size, and Location of Heat Sink Fins

The arrangement of fins on a heat sink significantly affects the flow of the coolant medium. Advancing the setup assists with decreasing liquid stream opposition in this manner permitting more air to go through a hotness sink. Its presentation is likewise dictated by the shape and plan of its blades. Upgrading the shape and size of the blades assists with expanding the hotness move thickness. By modeling, engineers can assess the performance of different fin shapes and arrangements.

4. Hotness Sink Fins: Electronics Cooling Efficiency

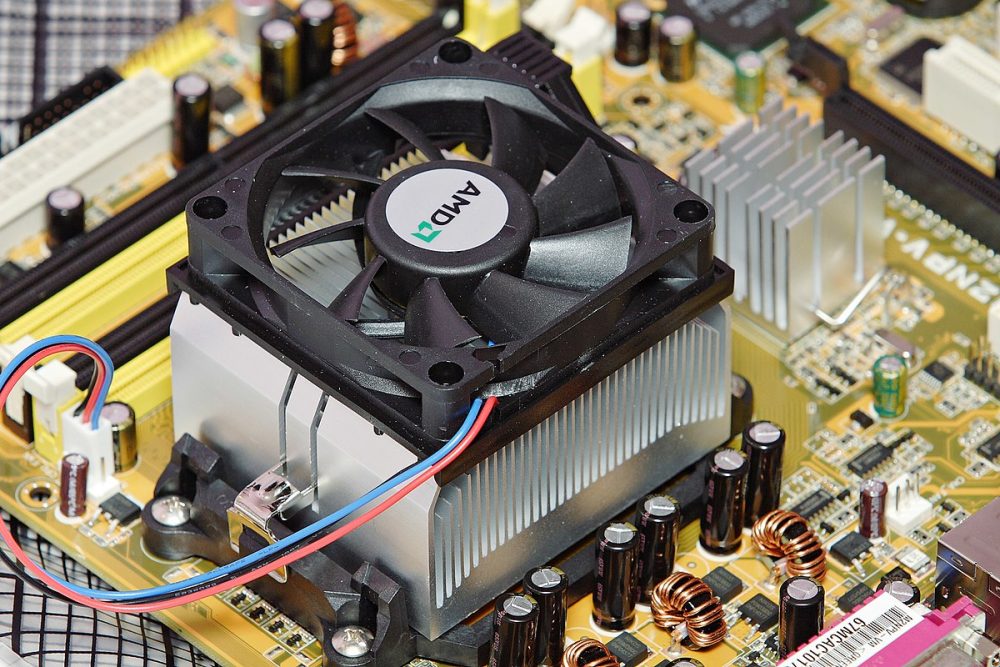

CPU Heatsink fan from an electronic gadget and scatter it into the encompassing coolant liquid. The hotness moved by a blade to the coolant medium abatements as the separation from the foundation of the hotness sink increments. Utilizing a material that has a higher warm conductivity and diminishing the perspective proportion of the blades help to support the balances’ general proficiency. The accompanying picture is essential for the consequences of a reproduction exploring the temperature qualities of a hotness sink plan.

- Hotness sink plan warm investigation with SimScale

- Temperature smoothes out: heat sink plan recreation did in an internet browser with SimScale

5. Step by step instructions to Dissipate Heat: Thermal Interface Material

Surface deformities, harshness, and holes increment warm contact obstruction along these lines diminishing the viability of a warm arrangement. These deformities increment the hotness stream obstruction by decreasing the warm contact region between an electronic part and its hotness sink, and thus the hotness sink productivity. Warm opposition is diminished by expanding the interface pressure and diminishing the surface harshness. Much of the time, there are cutoff points to these opposition decrease strategies. To defeat these cutoff points, warm interface materials are utilized. When choosing a thermal interface material for a specific application, consider the material’s electrical resistivity, contact pressure, and surface pore size.

6. Instructions to Dissipate Heat: Heat Sink Attachment Methods

You can improve the thermal performance of a heat sink by selecting the right method to attach it to an electronic device or component. The choice cycle should factor in both the warm and the mechanical necessities of the warm administration arrangement. Normal hotness sink connection techniques incorporate deadlock spacers, level spring clasps, epoxy, and warm tape.

- Hotness SINK EFFICIENCY

- Plan Conclusions

- heat sink configuration mounted on a printed circuit board

Hotness sinks are fundamental pieces of most electronic gatherings, power electronic gadgets, and optoelectronic parts. These uninvolved hotness exchangers disperse heat produced by electronic gadgets to guarantee that they are working inside the cutoff points determined by makers. A portion of the key factors that ought to be considered in heat sink configuration incorporate warm obstruction, material, blade design, balance size and shape, balance productivity. Lenovo thinkpad fan connection strategy, and warm interface material. By analyzing different heat sink models, engineers obtain calculations and parameters that provide optimal heat distribution.