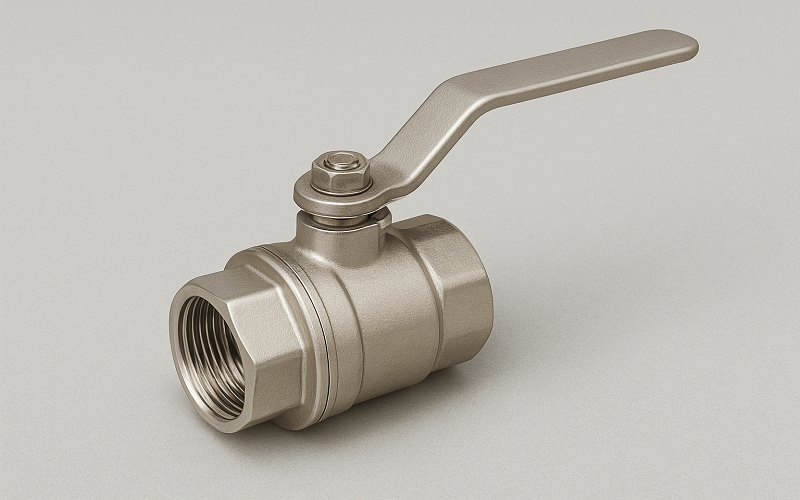

One essential element that supports all major industries is a reliable flow-control system. Power, water, gas, oil, chemical, and pharmaceutical sectors all depend on it to keep operations running. Stainless steel ball valves play a key role in these systems by controlling the flow of liquids and gases, even in the most demanding environments. Their consistent performance, rust-proof quality, and long-lasting durability make them vital to maintaining India’s industrial foundation.

As plants and pipelines grow, the stakes for every stainless steel ball valve manufacturer in maintaining business as usual operations have never been higher.

Flow Control in National Infrastructure Matters

The industrial chain is only as strong as its weakest mechanical part. Whether you operate a large power plant or manage a municipal water supply system, accurate flow control is essential for safe and efficient operations. Stainless steel ball valves help isolate fluid sections, regulate pressure, and provide quick shut-off during emergencies.

From steam in thermal power plants to aggressive chemicals in process industries and potable water in municipal systems, stainless steel ball valves deliver reliable performance. They withstand high pressure and fluctuating temperatures while maintaining a tight shut-off. In addition, their quarter-turn actuation ensures fast response times for the most critical applications.

Why Stainless Steel is the Material of Choice?

Its unique resistance properties to corrosion, oxidation and chemical attack make it the ideal material for a ball valve. For Indian industrial applications, the deterioration of material is a major issue due to the high relative humidity, salinity and chemical exposure as well as temperature fluctuation.

Grades like SS 304 and SS 316 are commonly used due to its good mechanical strength, clean surface finish, and durabitity. These features allow stainless steel ball valves to offer the same reliable sealing while preventing corrosion, pitting, and scaling. With this, costs of maintenance are lowered, downtimes minimized and assets in the infrastructure run over longer periods more reliable.

Supporting Key Sectors of Indian Economy

India has diverse industrial bases with specific flow control requirements applicable to a variety of sectors. Stainless steel ball valves in oil and gas Stainless steel ball valve is used to control high pressure hydrocarbons (oil and natural gas) as well as the maximum temperature of 360 degrees C. They direct steam and cooling water circulation in power generation. They can safely operate with acids, solvents and reactive compounds in chemical plants.

Sanitary stainless steel valve is widely used in pharmaceutical and food industrial, to avoid contamination or mix of liquid, and clean manufacturing. Corrosion resistant valves are critical to water treatment plants and desalination facilities that provide millions of people with safe water. Standing behind all of these uses is a reliable stainless steel ball valve manufacturer who has designed valves that deliver for the long term in harsh conditions.

Manufacturing Standards and Quality Expectations

The vibrancy of India valve community comes from it continual advancing in manufacturing standard. Today, the Indian valve manufacturing facilities incorporate CNC machining capabilities, sophisticated casting and forging machines, state of the art seal technology and several stages of performance testing. Every stainless steel ball valve is tested dimensionally, hydrostatic & pressure to ensure quality and performance.

Export-focused manufacturers also prioritize global online visibility and international compliance standards, which strengthens the competitiveness of Indian valves in global markets. This strict adherence to manufacturing norms ensures that valves used in India’s infrastructure sector operate reliably and meet all relevant standards, even under round-the-clock industrial usage.

Smart cities and infrastructure modernization

Ongoing investments in smart cities, industrial corridors, water systems, and renewable energy push industries to adopt next-generation flow-control solutions. Stainless steel ball valves now serve as a key component in modern automated factories.

As digital monitoring and automation expand, industries pair stainless steel ball valves with actuators and smart sensors. This setup supports real-time monitoring and remote control. It also enables predictive maintenance, helping industries build stronger and more efficient infrastructure.

Export Growth and Global Recognition

Today, India is not only meeting local demand but also exporting stainless steel ball valve products to the Middle East, Europe, Africa, and Southeast Asia. Indian manufacturers are globally recognized for competitive pricing, technical expertise, and flexibility in customization.

Established stainless steel ball valve manufacturers now serve EPC contractors, OEMs, and industrial distributors worldwide. This export growth strengthens India’s position as a global hub for industrial flow solutions. It also highlights the importance of stainless steel ball valves in construction projects in India and overseas.

Long Term Economic and Operational Benefits

And the long life of stainless steel ball valves is conducive to great long

term financial rewards. And fewer shutdowns Lower maintenance costs and reduced replacement cycles directly affect industrial profitability and operating stability. Infrastructure assets operate for longer periods without any disruption, leading to higher national productivity overall.

Even small leaks or valve failures can translate into substantial financial loss for “pipeline industries” that operate round the clock. With stainless steel ball valves, industries protect their investments and maintain safe operations throughout generations.

Conclusion

Stainless steel ball valves are essential to India’s industrial growth. Their durability, corrosion resistance, and multi-industry application help maintain safety and efficiency across energy, water, chemical, food, and pharmaceutical sectors. These valves operate reliably even in demanding environments.

Read More : Surgical Hand Gloves Manufacturer in India

As India’s infrastructure grows, stainless steel ball valve manufacturers will continue to strengthen the nation’s industrial backbone and ensure long-term reliability.