The air operated double diaphragm pump is a multi-purpose pump that can handle a wide range of fluids. It is a positive displacement (PD) pump with two diaphragms. It includes two pumping chambers which are alternately filled and released via the movement of bendy diaphragms. The diaphragms act as a barrier between the liquid and the surrounding air.

The operation of AODD pumps does not rely on or need the use of costly mechanical seals. Compressed air is supplied into and vented from air chambers on opposing sides of the diaphragms to provide the pumping motion. Air Operated Double Diaphragm Pump is often used in switch applications. They can also take care of lots of inputs, comprising sludges, slurries, abrasive, and shear-sensitive fluids. They are sturdy, dependable, and simple to maintain, but they can be loud and are confined to medium-pressure applications.

How Air Operated Double Diaphragm Pump Works

The two diaphragms are linked by a shaft that passes through the center section, which houses the air valve. The air valve’s role is to direct pressured air to the rear of diaphragm number one. Forcing it to leave the center part. The compressed air moved the foam on the primary facet of the bendy diaphragm. Then, using NRV, force the liquid on the opposite side of the diaphragm to take the chamber’s outward direction.

When this process is finished, the air pressure is transferred to the second flexible diaphragm chamber. When the second diaphragm travels forward, it pushes the first diaphragm backward through the linkage rod. Due to suction/vacuum, the first diaphragm back causes suction in the first chamber, and liquid enters the first chamber. The identical procedure is then repeated. Suction in the first chamber, discharge in the second. Suction in the second chamber and discharge in the first.

The Primary Benefits of Air Operated Double Diaphragm Pump

Due to their outstanding performance, they now play a significant part in the pump selection process.

- Easy layout: AODD pumps require minimum installation since they don’t have any spinning, sliding, or closely fitting elements. They can be used right away after being attached to a compressed airline, and they require very minimal maintenance while in use.

- Dry Running Capabilities: AODD pumps can run dry for a lengthy period without causing harm to the pump or its components. Pumps frequently run dry, notably in sump dewatering, tanker unloading, and tank over applications. Running dry may cause harm to other types of positive displacement pumps, reducing their service life.

- Effective solids management: Many AODD pumps can readily and efficiently handle solids-laden fluid without causing harm to the pump or the product.

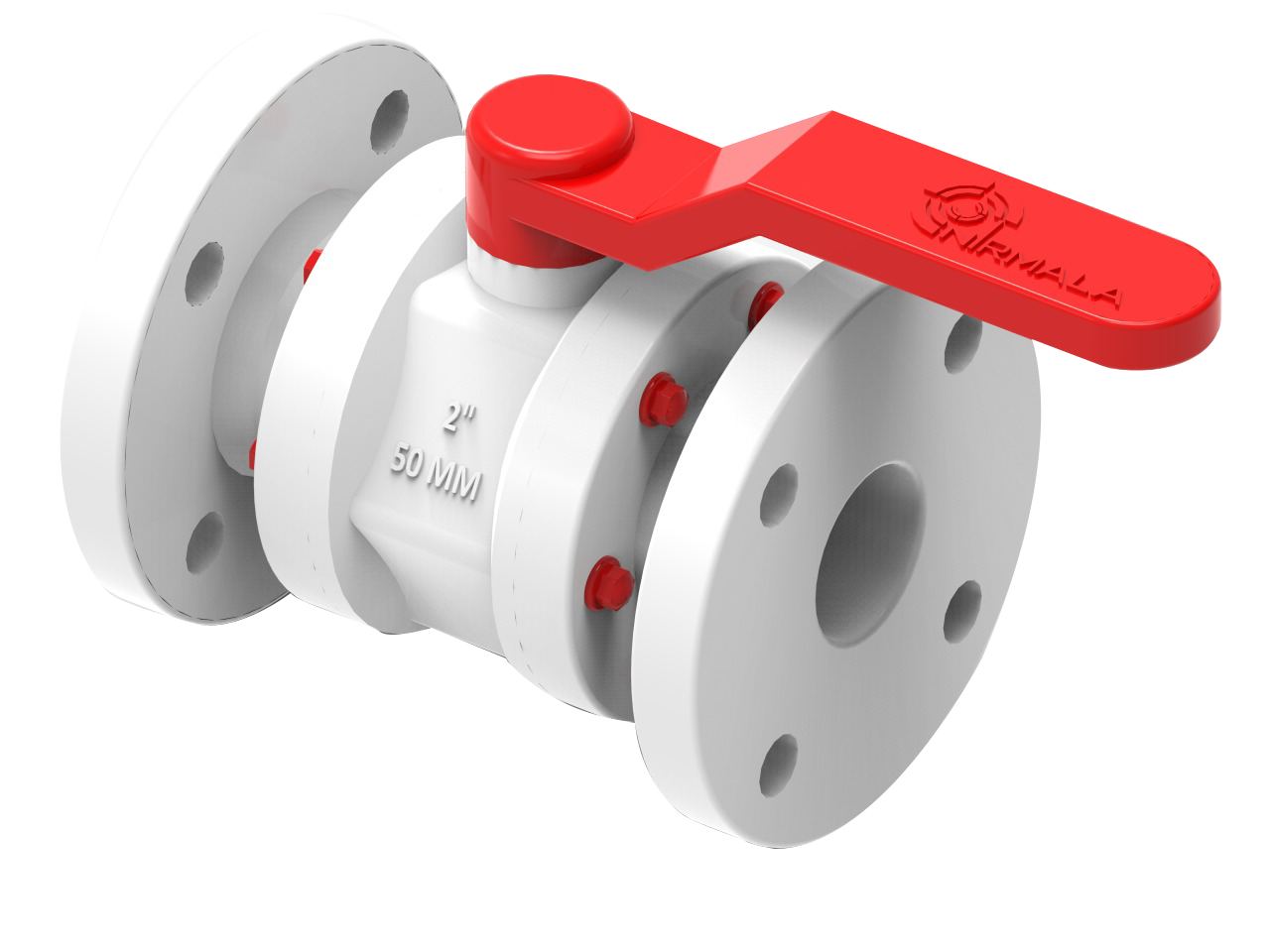

Ball-valve devices can handle solids up to about 0.75″ (19 mm) in diameter. Flap-valve devices can handle Semi Solids as small as a line size. - Deadheading happens when the fluid pressure equals the air input pressure driving the pump. When a valve on the pump’s fluid side is closed, the pump will develop pressure until it is equal and then cease pumping. When a valve on the pump’s fluid side is closed, the pump will develop pressure until it is equal and then cease pumping.

- Safety: AODD pump run on compressed air, which eliminates the need for a motor, power, or fuel, making them safer for employees. They’re also entirely sealed, which means they may be submerged in liquids completely or partially. Also, the food and beverage sectors use AODD pumps because they have a low risk of media contamination.

- Versatility and customization: AODD pumps can be made out of a variety of materials. As a result, they are exceptionally adaptable for a wide range of applications, including pure water and fluids containing 90% solids. Air-Operated Double-Diaphragm pumps are simple to modify and provide practically endless options for flow rate, pressure, media, and more.

- Also, AODD pumps do not froth or segregate the substance being pushed. These pumps are soft on the product being pushed. This is especially important when pumping a variety of goods that might be changed or damaged if sheared. Other pumping systems, such as centrifugal and gear pumps, have the potential to shear goods.

- Low buying costs in the beginning: AODD pumps are often less costly than other forms of positive displacement pumps like lobe, gear, or progressive cavity. They also don’t necessitate the purchase of pricey motors or controllers, nor do they necessitate professional installation.

- Self-priming: Self-priming AODD pumps do not require positive inlet pressure (NPSHA) to prime. This implies that these diaphragm pumps can be utilized as a sump pump and in situations where favorable suction conditions are not present.

- Submersible: Also, submerged pumps must have a hose connecting to the air exhaust and the exhaust pipe above the liquid level. So that no liquid enters the pump through the air exhaust.

Conclusion

As one of the leading air operated diaphragm pump suppliers, our objective is to supply you with the finest pump system possible for your specific application. Contact us now to learn more about the advantages of Air-Operated Double-Diaphragm pumps and to discuss all of your pump options and modifications. Contact Nirmala Pumps & Equipments immediately and one of our knowledgeable specialists will gladly answer any queries you may have.