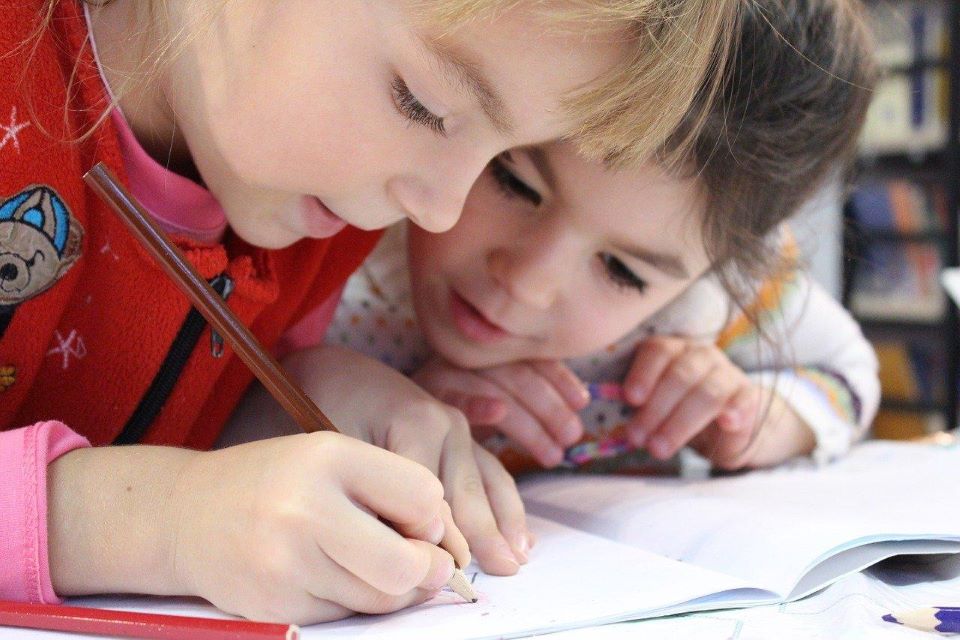

We invest heavily in handcrafting quality pencils and craftsman materials utilizing customary strategies passed down for six ages. Our experiences date to 1860, when Edward Weissenborn established the American Lead Pencil Co. in Hoboken, NJ. He was a creator and engineer and obtained 28 licenses for other developed hardware and cycles in making 360 various types of pencils. 2 offered the organization to The Reckford family in 1885. Then, in 1889, he established the pencil business in Jersey City with his son Oscar, which was later renamed The General Pencil Company. Buy Zindee products using the Zindee coupon Code and save extra bucks.

Stage 1

Pieces of graphite (a delicate, dull mineral) and dirt are put inside a gigantic turning drum. Huge rocks inside the drum pulverize the graphite and mud into a fine powder. Then water is added, and the combination is mixed in the drum for as long as three days.

Stage 2

Large wheels grind the dried mixture into a fine powder, and manufacturers add water again to create a smooth, workable paste.

Stage 3

After drying, the pencil leads are placed on a stove warmed to 1,800 degrees F. The serious hotness makes the tips smooth and hard, making great composing focuses.

Stage 4

Manufacturers apply a thin layer of adhesive to the slats and insert a pencil lead into each of the eight sections. Another grooved slat is quickly placed on top, effectively sandwiching the leads.

Stage 5

A similar machine cuts separated each support into eight different pencils.

Stage 6

A warmed metal stamp presses the organization’s name and a number – like a number 2 – on the pencil in foil or paint. The number demonstrates how complex the pencil lead is.

Stage 7

A machine extracts all the water from the blend leaving behind a dark muck. Here, a specialist places the slime in a bureau where the air dries and solidifies for four days.

Stage 8

The glue is pushed through a metal cylinder and looks like light poles.

Stage 9

Machines cut squares of Incense Cedar Wood, a sustainable asset, into wide braces. Eight shallow depressions are cut the long way into each mount. In one more piece of the industrial facility, the wood is ready.

Stage 10

Whenever the paste dries, the braces are taken care of through a cutting machine. Quick spinning steel sharp edges trim the wood into round or hexagonal shapes, each side in turn.

Stage 11

The pencils are sanded, and everyone gets five to eight layers of paint.

Stage 12

Workers tightly attach a metal ferrule around one end of each pencil. The pencils are then sharpened, packaged, and ready for use.

THE PENCIL MAKING PROCESS

Our guide to cedar pencil production highlights time-honored traditions combined with modern manufacturing facilities. Manufacturers dry the assembled product in a kiln to reach a uniform moisture level before sending it to the slat production plant.

Steps to Pencil Perfection

At the slat factory, workers cut pencil stock into “pencil blocks” slightly longer than the finished pencil length, and this extra length—known as the “trim allowance”—later plays a crucial role in production

Pencil Blocks are cut into “Pencil Slats” utilizing extraordinarily planned round saws. These saws are highly dainty to diminish how much “squander” is “sawdust.” Due to the wood’s average grain and imperfection attributes. To dispense with the imperfections and create an assortment of usable grades and handles of pencil braces. Braces without blemishes are designated “full handle.”

Manufacturers coat pencil slats with wax and color to create a consistent shade and improve the wood’s machining and sharpening performance. Inspectors then conduct a final review before packaging the slats and shipping them to pencil factories around the world.

At the Pencil Factory, a “Groover machine”

slices the groove into the supports to acknowledge the composing center (or “lead”).

Composing centers

Manufacturers blend graphite and clay to form sections for pencil cores. Colored pencils typically use wax-based cores, while specialty or surface-level pencils use other specific formulations.

A second scored brace is stuck onto the first –

making a “sandwich” – by a “lead layer” machine. At that point, the sandwiches are “clasped” and held firmly while the paste dries.

Once the paste dries, the pencil “sandwiches” move to a shaper, where they are first squared to ensure uniform length. Then, machines cut the sandwiches into pencil shapes such as hexagonal, round, or triangular.

After cutting, individual pencils are prepared for further processing. Inspectors remove any pencils with defects, such as off-center leads or chipped wood.

Next, each pencil passes through a machine that applies 4 to 10 layers of enamel, depending on the desired finish quality and color intensity. After painting, manufacturers wrap some pencils in decorative films or sleeves featuring intricate designs, while most pencils receive their brand names embossed on the surface using foil stamping. Then, they cut a groove to securely fit the ferrule.