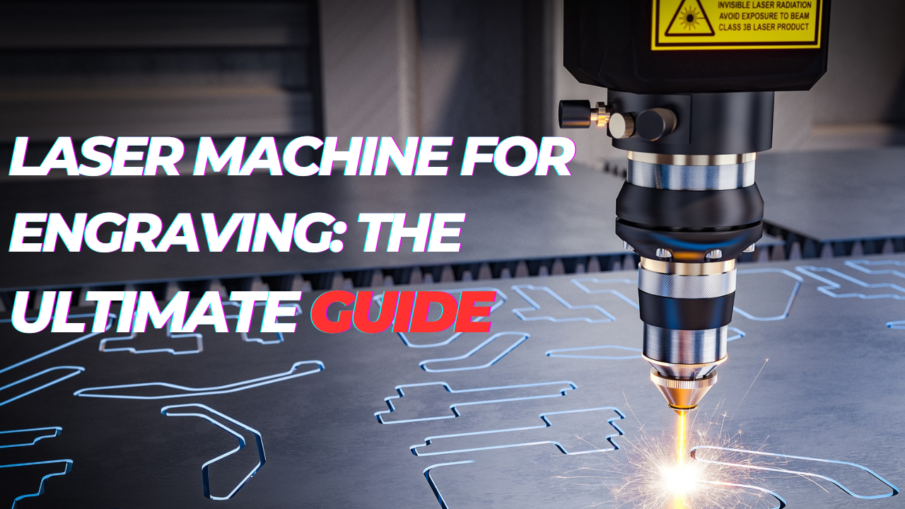

Laser machines for engraving have revolutionized the way people create intricate designs, logos, and texts on various materials. These machines are a go-to tool for many businesses and individuals looking to produce high-quality and precise engravings on a range of materials such as wood, plastic, glass, and metals. In this article, we will dive deep into the world of laser machines for engraving and explore how they work, their applications, and how to choose the best machine for your needs.

What is a laser machine for engraving?

A laser machine for engraving is a specialized tool that uses laser technology to create precise and permanent markings on a variety of materials. These machines are designed to etch or cut into the surface of the material, leaving behind an image or text that is sharp, detailed, and long-lasting. Laser machines for engraving are widely used in various industries, including manufacturing, woodworking, jewelry making, and personalization.

How does a laser machine for engraving work?

Laser machines for engraving use a highly focused beam of light to vaporize the material’s surface. The laser beam is directed by a series of mirrors and lenses, and the beam’s intensity and duration are controlled by a computerized system. This process creates a precise and permanent marking on the material, with little or no damage to the surrounding area.

Types of laser machines for engraving

There are three main types of laser machines for engraving: CO2 laser machines, fiber laser machines, and diode-pumped laser machines.

CO2 laser machines

CO2 laser machines use a gas-filled tube to produce a laser beam. These machines are best suited for engraving non-metallic materials such as wood, plastic, glass, and acrylic.

Fiber laser machines

Fiber laser machines use a solid-state laser source and are ideal for engraving metals such as steel, brass, and aluminum. They are also used for marking and engraving plastics and other non-metallic materials.

Diode-pumped laser machines

Diode-pumped laser machines use a semiconductor diode as the laser source. These machines are highly efficient and ideal for engraving on a wide range of materials such as metals, plastics, and ceramics.

Applications of laser machines for engraving

Laser machines for engraving are used in various industries and applications. Here are some of the most common uses of these machines:

Woodworking

Laser machines for engraving are widely used in the woodworking industry to create intricate designs, logos, and texts on wood. These machines can engrave on various types of wood, including hardwood, softwood, and plywood.

Jewelry making

Laser machines for engraving are also used in jewelry making to create intricate designs on metal surfaces. These machines can engrave on a range of materials such as gold, silver, brass, and stainless steel.

Personalization and customization

Laser machines for engraving are also popular in the personalization and customization industry. These machines can engrave names, logos, and other designs on various objects such as phone cases, keychains, and personalized gifts.

Industrial manufacturing

Laser machines for engraving are commonly used in industrial manufacturing to mark and engrave serial numbers, barcodes, and logos on products. These machines can also be used to cut and engrave materials for industrial applications.

Medical devices

Laser machines for engraving are used in the medical industry to mark medical devices with identification numbers, logos, and other information. This helps to track and trace medical devices and ensure their safety and authenticity.

Factors to consider when choosing a laser machine for engraving

When choosing a laser machine for engraving, there are several factors to consider. These include:

Power and wattage

The power and wattage of a laser machine determine its speed and cutting depth. Higher wattage machines are faster and can cut deeper than lower wattage machines.

Engraving area

The size of the engraving area determines the maximum size of the object that can be engraved. Choose a machine with an engraving area that is suitable for the objects you plan to engrave.

Materials compatibility

Different laser machines are compatible with different materials. Ensure that the machine you choose is suitable for the materials you plan to engrave.

Software compatibility and ease of use

Choose a machine that is easy to use and compatible with the software you plan to use. Look for machines that come with user-friendly software or can be easily integrated with popular design software.

Maintenance and support

Choose a machine that is easy to maintain and comes with good customer support. Look for machines that come with warranties and have a good reputation for reliability.

Safety considerations when using a laser machine for engraving

Laser machines for engraving can be hazardous if not used properly. Always follow the manufacturer’s instructions and safety guidelines. Wear protective equipment such as safety glasses and gloves when using the machine. Ensure that the machine is placed in a well-ventilated area to prevent the buildup of toxic fumes.

Conclusion

Laser machines for engraving are a versatile tool that can be used in various industries and applications. When choosing a laser machine, consider factors such as power and wattage, engraving area, materials compatibility, software compatibility, and maintenance and support. Always follow safety guidelines when using a laser machine for engraving.

FAQs

- Are laser machines for engraving expensive?

- Laser machines for engraving can range in price from a few hundred dollars to several thousand dollars, depending on the machine’s specifications and features.

- Can laser machines for engraving engrave on curved surfaces?

- Yes, laser machines for engraving can engrave on curved surfaces using a rotary attachment.

- Can laser machines for engraving cut through materials?

- Yes, laser machines for engraving can cut through certain materials, but this depends on the machine’s power and the thickness of the material.

- How often do laser machines for engraving need maintenance?

- Laser machines for engraving require regular maintenance, including cleaning and alignment. The frequency of maintenance depends on the machine’s usage and the manufacturer’s recommendations.

- Can laser machines for engraving be used for mass production?

- Yes, laser machines for engraving are often used in mass production to create precise and consistent markings on products. They are ideal for creating high-quality and permanent marks on a range of materials.

- Are there any safety concerns when using laser machines for engraving?

- Yes, laser machines for engraving can be hazardous if not used properly. Always follow the manufacturer’s instructions and safety guidelines, wear protective equipment such as safety glasses and gloves, and ensure that the machine is placed in a well-ventilated area to prevent the buildup of toxic fumes.

- What is the lifespan of a laser machine for engraving?

- The lifespan of a laser machine for engraving depends on its usage and maintenance. With proper maintenance, a laser machine can last for many years.

- Can laser machines for engraving be used to engrave photographs?

- Yes, laser machines for engraving can engrave photographs onto a range of materials such as wood, acrylic, and metal. However, the quality of the engraving may vary depending on the material and the quality of the photograph.

- How do I choose the right laser machine for my business?

- When choosing a laser machine for your business, consider factors such as the size and type of objects you plan to engrave, the materials you plan to use, and your budget. It is also important to consider the machine’s features and specifications, as well as its maintenance and support.

- Can laser machines for engraving be used for other applications besides engraving?

- Yes, laser machines for engraving can also be used for cutting, welding, and marking a range of materials. However, the machine’s capabilities may vary depending on its specifications and features.

Conclusion:

In conclusion, laser machines for engraving offer a highly efficient and versatile method of creating permanent and high-quality marks on a range of materials. They are widely used in various industries such as manufacturing, jewelry, and promotional products. With advancements in technology, laser machines have become more accessible and affordable, making them an attractive option for small businesses and hobbyists. When choosing a laser machine for your business, it is important to consider factors such as the size and type of objects you plan to engrave, the materials you plan to use, and your budget.