Valves control the flow of liquids, gases, and steam in pipelines and machines across all industrial processes. Industries such as oil and gas, chemical processing, water treatment, pharmaceuticals, food production, and power generation use valves. A valve’s performance can directly affect safety, efficiency, and overall system reliability. Valves operate under varying temperatures, pressures, and corrosive conditions. Therefore, it is crucial that they meet strict international testing and certification standards before installation. This is where valve testing, quality certifications and engineering standards are important.

Why Valve Testing Matters?

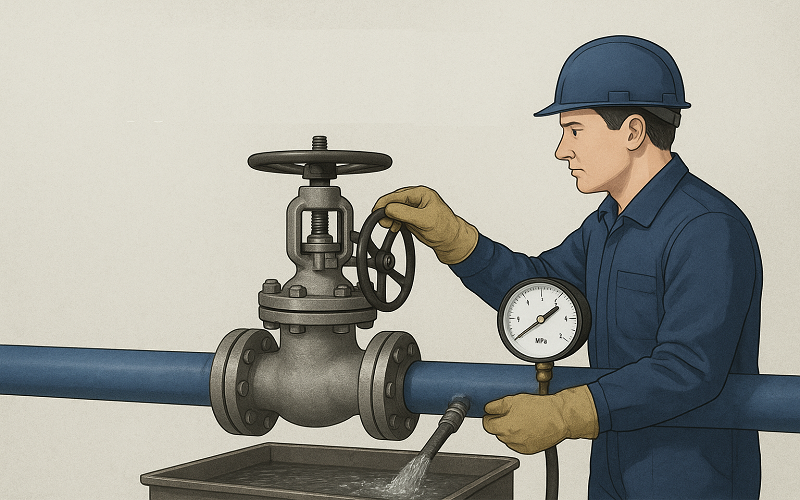

Testing valves ensures they operate according to design without leakage, deformation, or mechanical failure. A valve may look perfect externally, but its internal sealing faces and moving parts must function correctly in practice. Testing determines if the valve can accept pressure, temperature, media and flow requirements with no deterioration of service over time. Valves that are inadequately tested also escalate the potential for leaks, contamination, shutdowns, fire dangers and expensive equipment failures. As a result, each reputable valve manufacturer India conducts a systematic testing sequence to validate the safety and reliability of the valve before it is placed into service.

Types of Valve Testing Explained?

The following are the tests that valve manufacturers may carry out depending on agency overview of type, application and customer specification.

- The hydrostatic test (most common), involves filling the valve with water and pressurizing it well in excess of the pressure rating, to verify that the strength and sealing characteristics are adequate.

- Pneumatic tests use air (or another gas) to pressure test where water cannot be used or must not be used. Function tests the valve opening and closing action, stem torque operation, and seat to ball or disc/plug sealing compatibility.

- For corrosion resistance of the valves in acidic or marine environments, testing on corrosive chemicals and marine exposure tests are carried out for long term service.

- Some industries require life cycle testing in which the valve is operated thousands of times to determine its performance under continuous mechanical movement.

- Engineers perform thermal testing on high-temperature valves by measuring expansion and contraction. This ensures the valve remains leak-tight during thermal cycling.

What Are Valve Quality Certifications?

Independent international testing bodies issue quality certificates to confirm that a valve meets safety, material, and performance standards. Certified control valves give customers confidence that engineers designed them according to globally accepted engineering principles. ISO certifications like ISO 9001 verify that every industrial valve manufacturer India stick to a trusted quality management system in the production procedure. API (American Petroleum Institute) certifications like API 600, API 607 or API 6D are requisites in a number of oil and gas projects and ensure the valve is able to handle harsh industrial settings. The fire safe certifications guarantee the valve tight sealing even during a fire. Material certificates like EN 10204 3.1 indicate on the raw materials and detail their chemical and mechanical properties. Combined, these are the shields of security that protect industrial workplaces from receiving anything but a reliable valve.

Understanding Valve Standards

Although certifications attest to conformity, international standards are engineering rules for which valves shall be built on. Standards define characteristics such as dimensions, pressure and temperature ratings, materials of construction, etc. Typical pressures ratings and metal properties for industrial valves are found in ASME and ASTM standards. European markets and water and at gas distributing valves are frequently stated to DIN or EN standards. API standards are highly critical for oil and gas valves as these specify the design and testing requirements of ball, gate, globe, plug and check valves. These standards help to govern that valves made by several manufactures will work together in the same pipeline system.

Why Testers and End Users Care about Testing and Standards?

Though testing and certifications occurs in the factory, it is felt greatly at installation location. Certified and well tested valves minimize the risk of failure, maintenance stops and safety situations. They prolong the life of pipelines and machinery: each valve is tested for pressure, tightness and resistance to corrosion. Companies handling dangerous or high-value products need certified valves. Certified valves protect equipment, workers, and the environment. Choosing a valve with the wrong certification may seem cheaper initially. However, it significantly increases the risk of leaks, operational stoppages, and maintenance or replacement costs.

Conclusion

Valve testing, quality certification and engineering standards are some of the key elements that encourage performance, reliability and worker safety. Each valve is tested for pressure bearing capacity, sealing of leaks and corrosion resistance as well as an ease in operation. International certifications and standards serve to ensure the customer that the product they are buying is secure and high performing. For those responsible for purchasing, installing or maintaining the valves in a plant must first understand what these requirements are in order to select valves that will work reliably and at cost-effective levels for their entire service life.