Pneumatics and hydraulics are like the muscles and sinews of the mechanical world, powering everything from the smooth operation of factory machinery to the dependable brakes in your vehicle. Each system has its unique strengths, offering different advantages depending on the needs of your project. Below, we delve into the specifics of these two power systems to guide you in choosing the right one for your needs.

What’s the Deal with Pneumatics and Hydraulics?

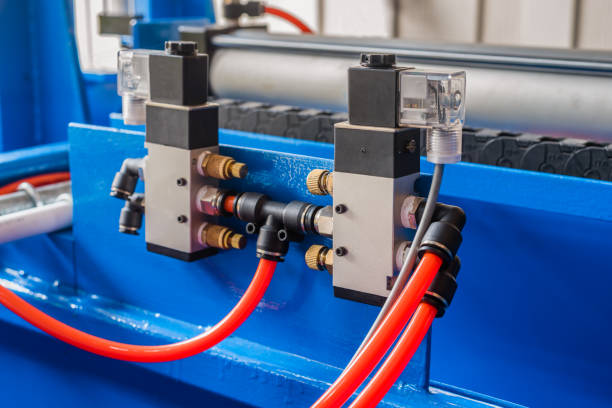

Pneumatics operates on the principle of gas compression, primarily using air to transmit power. Air, being easily compressible, offers a flexible medium for energy transfer. Picture a balloon: when you blow air into it, the balloon expands; when you let the air out, the balloon flies around. Pneumatics harnesses this principle to power tools, machinery, and even some toys. It’s particularly favored for its cleanliness (since it uses air) and its efficiency in repetitive tasks, such as in assembly lines where precision and speed are paramount.

Hydraulics, on the other hand, is all about using liquids—typically oil—to transmit power. Unlike air, liquids are virtually incompressible, making them highly efficient at transferring force. Imagine pressing down on a syringe filled with water; the water doesn’t compress but instead moves to exert pressure elsewhere. This principle allows hydraulics to move heavy loads, control machinery with great precision, and perform tasks requiring significant force. From construction equipment to automobile brakes, hydraulics plays a crucial role in providing the power needed to make our modern world work.

Related blog: How to Repair a Hydraulic Hose in Just 6 Steps

Why Choose Pneumatics?

Choosing pneumatics is like opting for a lightweight, nimble athlete to complete tasks that require speed, agility, and precision. This system is perfect for applications where cleanliness and safety are paramount, as it uses air—the most abundant resource available. Pneumatics is incredibly versatile, powering a wide array of tools and systems, from the air brakes on buses and trucks to the pneumatic tubes that transport capsules in hospitals and banks. It’s the go-to choice for environments where fire hazards must be minimized, thanks to its use of non-flammable air. Additionally, pneumatic systems are relatively simple to design, install, and maintain, making them a cost-effective solution for many industrial applications.

And Hydraulics?

Hydraulics is the powerhouse, the strongman of the two. Its ability to handle immense weights and exert tremendous force makes it indispensable for heavy-duty applications. Consider the construction industry, where hydraulic machinery like excavators and bulldozers move earth and lift heavy materials daily. Or the manufacturing sector, where hydraulic presses mold, form, and shape materials with precision and strength. The principle behind hydraulics—using fluid to transmit power—allows for smoother, more controlled movements, which is essential when the task at hand requires delicacy despite the force applied. Moreover, hydraulic systems can be scaled up or down, making them suitable for a vast range of applications, from large-scale construction projects to precision engineering in aerospace and automotive industries.

Related blog: How to Rebuild a Hydraulic Cylinder?

Hydraulic Repair and Your Local Hydraulic Shop

Like any technology, hydraulic systems require maintenance to stay in peak condition. Hydraulic repair services are vital for diagnosing and fixing issues that could lead to system failures, such as leaks, seal wear, or contamination of the hydraulic fluid. A local hydraulic shop can be a treasure trove of expertise, offering services from routine maintenance to complex repairs and parts replacement. These specialists understand the nuances of hydraulic systems, ensuring that machines continue to operate efficiently and safely. Regular maintenance not only extends the lifespan of the equipment but also prevents costly downtime and repairs, making it a critical consideration for businesses relying on hydraulic power.

Which One Should You Choose for Your Project?

Deciding between pneumatics and hydraulics comes down to the specific needs of your project. If you require fast, repetitive motion or are working in a clean environment where safety is a concern, pneumatics is your best bet. Its simplicity, efficiency, and cleanliness make it ideal for light to medium-duty applications. However, if your project involves moving heavy loads or requires significant force and precision, hydraulics will likely be more suitable. Its unparalleled power and control enable it to tackle the most demanding tasks with ease. Consider the nature of the work, the environment in which the system will operate, and the level of force required when making your decision.

Related blog: Hydraulic Repair for Chilliwack’s Industrial and Agricultural Needs

Making It Better for You

Choosing the right system for your project is just the beginning. To truly enhance your work and ensure the best outcomes, engage with experts, seek out quality equipment, and prioritize maintenance. Whether you lean towards pneumatics for its agility and safety or hydraulics for its strength and precision, remember that the effectiveness of either system depends on well-informed choices and ongoing care. By focusing on quality, efficiency, and reliability, you can ensure that your project not only meets but exceeds expectations.

Conclusion

Pneumatics and hydraulics each have unique strengths that make them well-suited to various tasks. By understanding these systems thoroughly, you can make informed decisions that leverage their capabilities for your projects. Whether you need the swift precision of pneumatics or the formidable power of hydraulics, choosing the right system will help you achieve your goals with excellence. At Delange’s Industries, we understand the importance of having the right tools and support for your project. That’s why we offer a wide range of high-quality pneumatics and hydraulics solutions tailored to meet your specific needs. Our team of experts is here to guide you through selecting the perfect system for your project, ensuring you have the power and precision required to succeed.

Bio: Sonali Jha is the Founder of Make Vision Clear, a digital marketing agency. She has 5+ years of industry experience and has worked with top brands worldwide. Sonali began her career as an intern in digital marketing and quickly developed expertise in the field. She is passionate about helping businesses grow with her creative strategies and campaigns.