Stainless steel (SS) has gained popularity as a popular material for creating various products. Its versatile characteristics and resistance to corrosion make it perfect for numerous applications such as kitchen appliances, medical equipment, and architectural designs. One of the most common uses of SS is in the form of sheets. SS sheets are widely used in different industries due to their durability and strength. This blog post will guide you on the SS sheet design process, showcasing the various aspects that make it one of the most widely used materials in manufacturing.

What is SS Sheet Design?

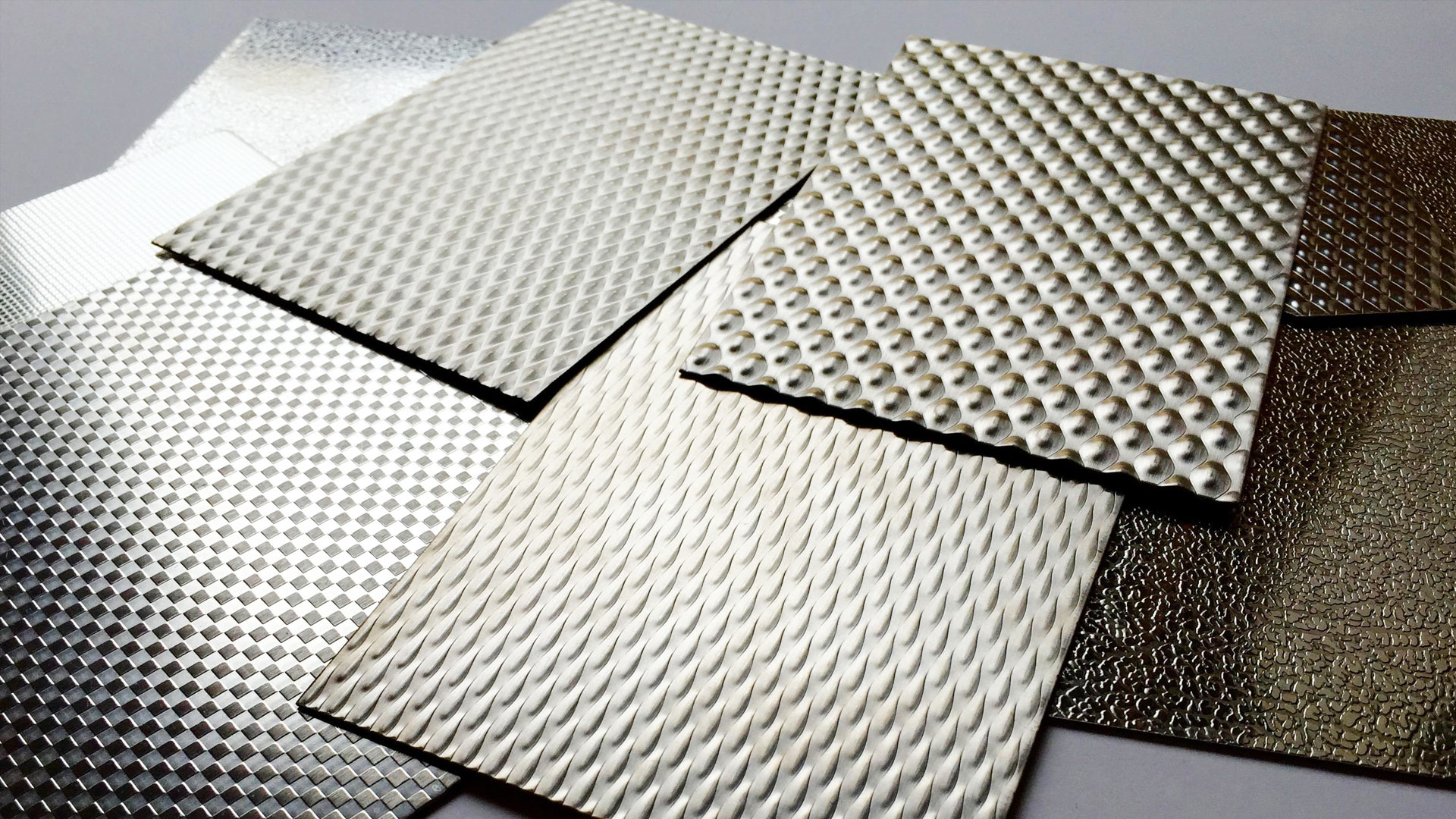

SS (Stainless Steel) sheet design creates functional and aesthetically pleasing products or structures using stainless steel sheets. Design considerations include the choice of stainless steel grade, thickness, and finish, as well as the incorporation of patterns, textures, and shapes to achieve a desired visual appeal. SS sheet design finds applications in architecture, interior design, industrial equipment, and custom fabrication, focusing on corrosion resistance, durability, and, often, a modern and sleek appearance. Whether used in architectural facades, interior finishes, industrial machinery, or custom-made products, SS sheet design combines material selection, engineering, and creative elements to meet specific project requirements and aesthetic goals.

Uses of SS Sheet Design

Architectural Cladding: Stainless steel sheets are used as building facades, wall cladding, and roofing material in architectural design due to their durability, corrosion resistance, and sleek appearance.

Interior Decor: SS sheets are employed for interior design elements like countertops, backsplashes, and wall panels, adding a modern and hygienic touch to kitchens and commercial spaces.

Industrial Equipment: SS sheets are utilized in the manufacturing of industrial equipment, such as tanks, pipelines, and machinery components, where resistance to corrosive substances is critical.

Automotive Parts: Stainless steel is used in the automotive industry for various components, including exhaust systems, trim, and grilles, due to its strength and resistance to rust.

Medical and Pharmaceutical: Stainless steel sheets are employed in the healthcare industry for sterile equipment and furniture, as well as for cleanroom construction.

Food Processing: SS sheet design is essential in the food industry for equipment like preparation tables, sinks, and storage shelves due to its easy-to-clean properties and resistance to staining.

Custom Fabrication: Stainless steel sheets are used in custom fabrication projects, including sculptures, signage, and bespoke architectural features, where the material’s versatility and aesthetics are valued.

Materials used in the manufacturing of SS Sheet Design

Designing the SS Sheet

The first step in creating an SS sheet is the design process. The design ensures that the product meets the end user’s needs. Designing SS sheets requires thorough consideration of different factors, such as the material composition, thickness, dimensions, and intended usage. With the right design, it becomes easier to produce SS sheets that meet the required custom specifications.

Material Composition

Choosing the right material composition for your SS sheet is essential. Two of the most popular alloys used in SS sheet production are 304 and 316 stainless steel. The former contains a high concentration of chromium and nickel, making it corrosion-resistant and perfect for use in food processing equipment. The latter is ideal for use in saline and marine environments due to its high resistance to saltwater corrosion.

Sheet Thickness

SS sheets can be obtained in different thicknesses ranging from .004″ to .250″. It is crucial to consider the intended use of the sheet when selecting the appropriate thickness; thicker sheets are stronger and have a longer lifespan.

Dimensional Considerations

The dimensions of the SS sheet are another crucial factor when it comes to design. The desired use of the product determines the size of the required sheets. There are no standard sizes for SS sheets; thus, each sheet is designed based on the intended application.

Finishing Options

SS sheets can be finished using different methods. Designers can select from finishing processes like polished, brushed, or blasted finishes. Each option offers a unique look that appeals to different customers.

Conclusion:

Stainless steel sheets have become popular due to their durability, strength, and aesthetic appeal. Designing SS sheets is a crucial process that requires a keen eye on various factors like the material composition, dimensions and finishing options. In doing so, it becomes easier to produce top-quality SS sheets that meet the customers’ needs. With the above insights, you can approach the SS sheet design process with the confidence needed to create useful products that meet stringent quality standards.